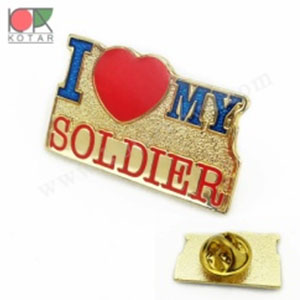

Epoxy On Metal Lapel Pins

2023/01/11

There are many steps for makingepoxied metal lapel pins, do you know the last step?

The last step for making metal lapel pins is adding a layer oftransparent resin onto the surface of metal lapel pins to protect designs/paints or polished surface, this kind of resin iswidely called “epoxy”. After adding epoxy ,the surface of metal lapel pins looks slightly coved and bright, andmetal lapel pinsare smooth when touch surface.

Epoxy is consisted of high-purity epoxy resin, curing liquid and other material composition, curing liquid has waterproof, glittering and translucent characteristics. When metal lapel pins adding epoxy, not onlyhavea good protective effect for metal lapel pins, but also increase metal lapel pins’surface with gloss and brightness, and it seems 3D effect looking from side view of metal lapel pins.

Epoxy is used in printing metal lapel pins widely as well as soft enamel metal lapel pins, sometimes epoxy is not used onto whole metal lapel pins but partly only in order to keep metal texture of metal lapel pins and show the advantage of epoxy in the meantime. Glitter isappliedinto epoxy to make metal lapel pins brighter and more ablaze.

Sample shown is for reference only